Digital Twins: The Industrial Revolution of the 21st Century

Mon, 12 Jun 2023

As technology advances, digital twins are poised to become even more indispensable across various industries. From manufacturing and infrastructure to healthcare and urban planning, the applications of digital twins are vast and transformative. They accelerate innovation, reduce downtime, and optimize resource utilization, fostering sustainable practices and driving progress.

ASSIST Software is already working on projects involving digital twins, and we are excited to have the opportunity to explore such a great topic. We're thriving, and so could you!

A digital twin definition:

A digital twin serves as a virtual counterpart of a physical entity, encompassing objects, processes, services, or environments. It closely resembles its real-world image in both appearance and behavior.

The scope of a digital twin can vary, ranging from replicating individual physical objects like jet engines or wind farms to larger entities such as buildings or even entire cities. Additionally, digital twin technology can simulate and replicate processes, enabling data collection for predictive analysis and performance evaluation.

At its core, a digital twin is a computer program that utilizes real-world data to create simulations, enabling predictions about the performance of a product or process. These programs leverage technologies such as the Internet of Things (IoT), artificial intelligence (AI), and software analytics to enhance their capabilities.

Our personal experience with digital twins in aerospace

PARS, a research and development initiative, has been awarded as part of the CENTRIC project: Center for knowledge transfer to enterprises in the ICT field.

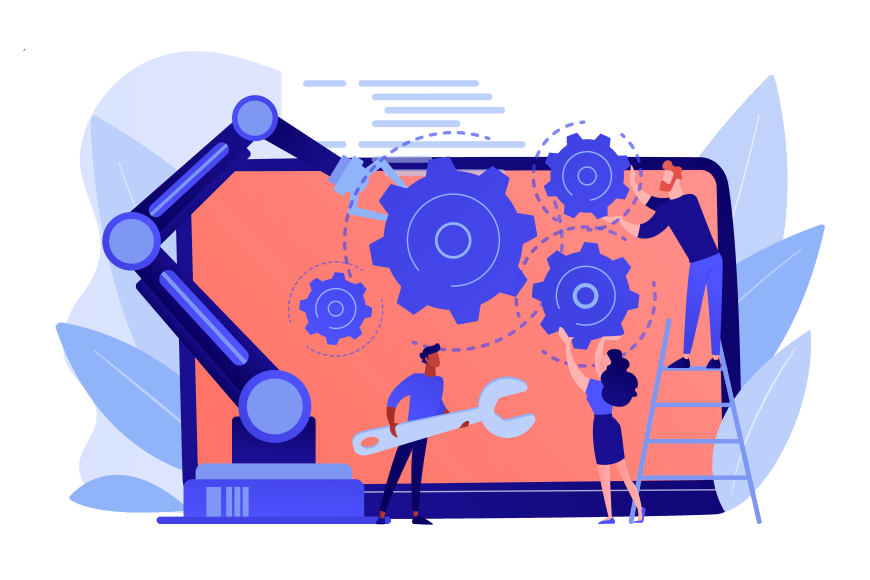

The Drone Vector Autonomous Recognition and Support Platform (PARS) research project aims to provide a solution that assists public authorities in critical situations requiring rapid response, efficient resource coordination, and seamless information flow. The proposed solution enables swift identification of vulnerabilities and the generation of dynamic, situation-specific remedies.

One of ASSIST Software's tasks within the project is the development of an Image Recognition module that can accurately identify real-life objects. This module will undergo training using high-quality synthetic images.

This module will enable computers to recognize and categorize objects just like humans do. By training it with synthetic images that closely resemble real-life objects, the module will learn to identify and classify them accurately when encountered in the physical world. This cutting-edge approach utilizes artificial intelligence and machine learning to enhance the module's understanding and interpretation of visual information.

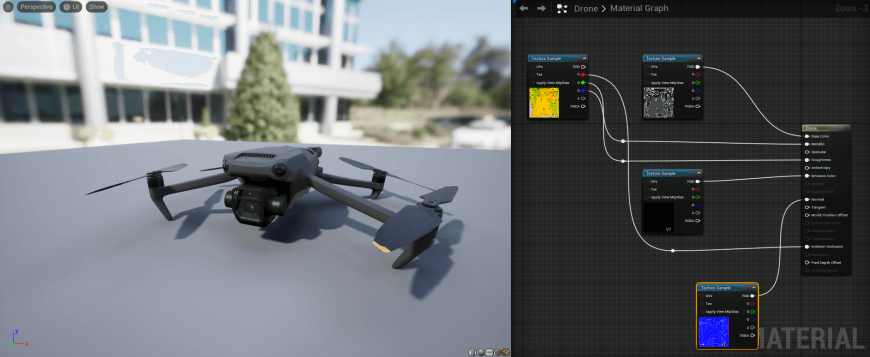

One of the cool things we're working on is creating an API connector that allows agents to be trained within Unreal Engine 5. This connector will enable seamless integration between the training environment and the powerful capabilities of Unreal Engine 5, opening up new possibilities for agent training.

Additionally, we're also developing a semi-procedural simulated environment within Unreal Engine 5. This environment will serve as the training ground for our agents, which in this case are drones. It's like a virtual playground where the drones can learn and improve their skills in a safe and controlled setting.

What other industries using digital twins right now?

1. Digital Twins in Healthcare

By leveraging digital twins, healthcare practitioners and researchers can simulate and analyze the effects of new products or services on virtual models that closely resemble actual patients or scenarios. This enables them to gain valuable insights, evaluate potential outcomes, and make informed decisions.

2. Digital Twins in Manufacturing

Are we on the cusp of a new industrial revolution? Many experts say that the age of Industry 4.0 has already started.

In Industry 4.0, digital twins empower organizations to optimize operations, increase productivity, and enhance overall efficiency. They enable predictive maintenance, allowing timely interventions and reducing downtime. Additionally, digital twins support virtual simulations, enabling scenario planning, testing, and optimization before implementing changes in the physical environment.

3. Digital Twins in Construction

Like other industries, digital twins empower construction crews to understand their projects and make timely adjustments comprehensively. This enables the creation of optimized structures and overall project efficiency. By visualizing and analyzing the digital twin, construction teams can identify potential issues or areas for improvement. They can swiftly implement changes and continue the project without causing delays or extending construction timelines.

Could your business become an Industry 4.0 pioneer? Are digital twins the optimal solution for you? How can ASSIST Software help you?